So long as motors have existed, there’s been a want to make sure that they work at the optimum heat range and that coolant is definitely and freely available. Both main forms of coolant are usually either air or drinking water structured liquids both which operate when you are circulated around the engine to avoid it from overheating.

For several years, the tabs on coolant levels were in no way completed or if it had been, after that at best a cursory dipstick was used. During days past, engines were much bigger and comparatively inefficient therefore hook loss of coolant didn’t present such a lot of an issue, but as engine style has evolved through the years and newer lighter components came into use then your repair or replacement expenses of motors damaged by way of a catastrophic lack of coolant intended that the existence of coolant was important and that there would have to be an alarm if the coolant fell below a motivated level.

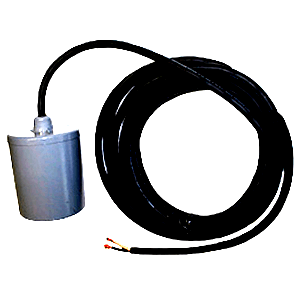

Frequently used nowadays is a little single point Float switch which will make or break once the coolant level falls beneath some level. The unit is cheap, simple to in shape and tolerably efficient. They do have problems with the consequences of vibration, and continual slosh of liquid in the reservoir and mechanical failures are usually very common. Realizing that systems have shifted both in sensing products and engine management techniques, engineers started to specify solid condition coolant level switches ought to be fitted for several reasons.

The capacitive switch uses precisely the same technology because of the capacitive sensor but uses capacitance to supply a “switching condition” on connection with liquid instead than a continuing measurement dependent on liquid level. The basic principle of the liquid degree switch is simple, and the means of accomplishing it are extremely various and use an array of different technologies, but contemporary capacitive switches, possess their very own embedded microprocessor, allowing them to end up being programmed to accommodate an array of switching choices, whether in coolants, natural oils or fuels.

The first thing you need to do would be to place the tool against the plastic container. You may use these specialty products in cases where the container will be opaque and can’t be opened up, or in the instances where the liquid may be dangerous if subjected to the open air.

The second thing that you should do is to proceed the sensor below the very best of the tool. You need to view the sensor for the indication which it really is detecting the liquid on the far side of the container. It is frequently pointed out by either the flashing lighting or the audible beep.

How about the Float Switches

Fluids levels inside containers might need to end up being monitored and handled for several different reasons. It might be essential to know whenever a receptacle gets low on liquid or on top of fluid and appropriate activity may then have to be taken.